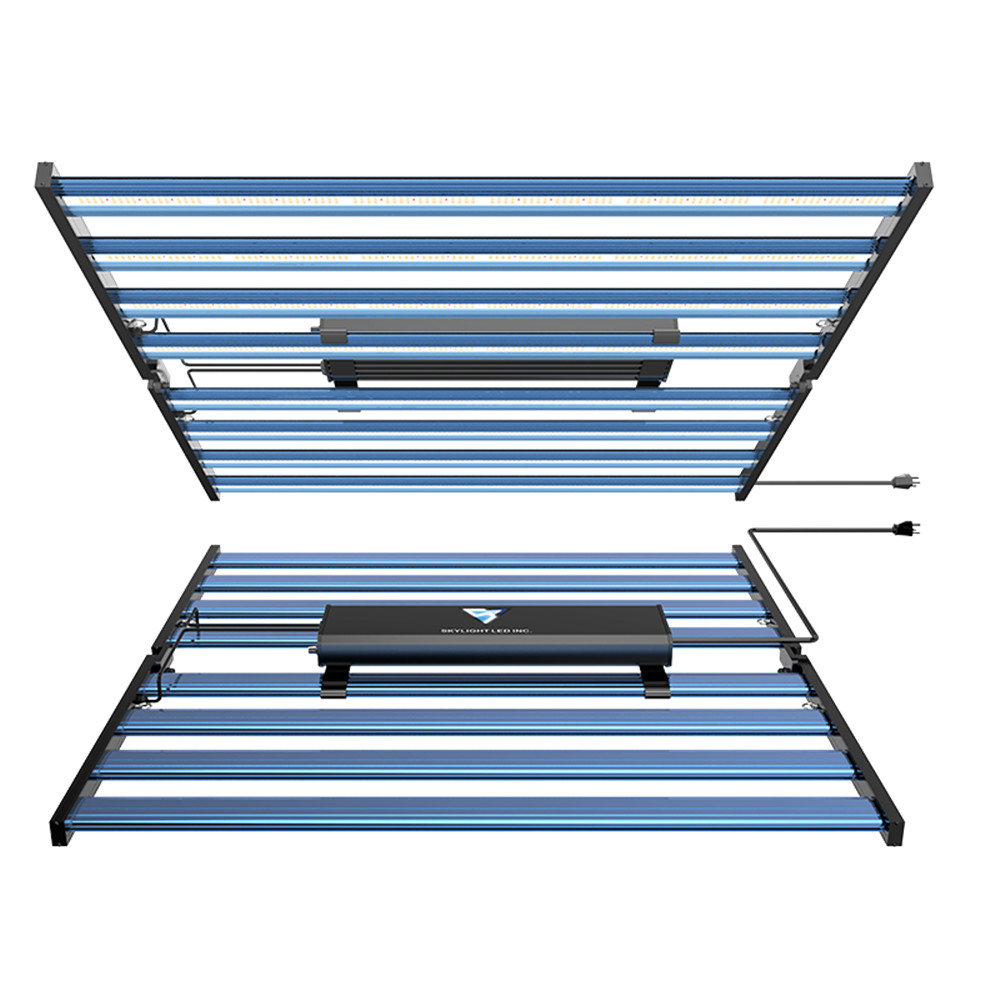

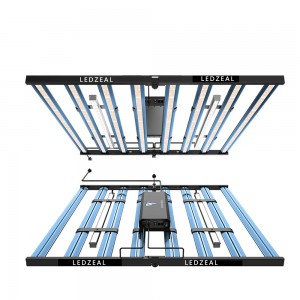

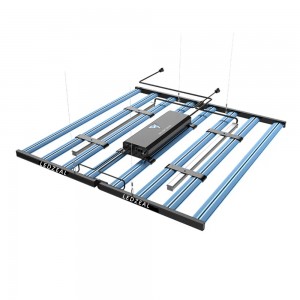

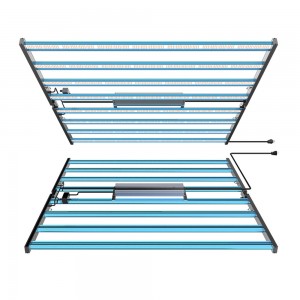

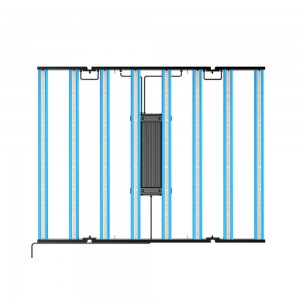

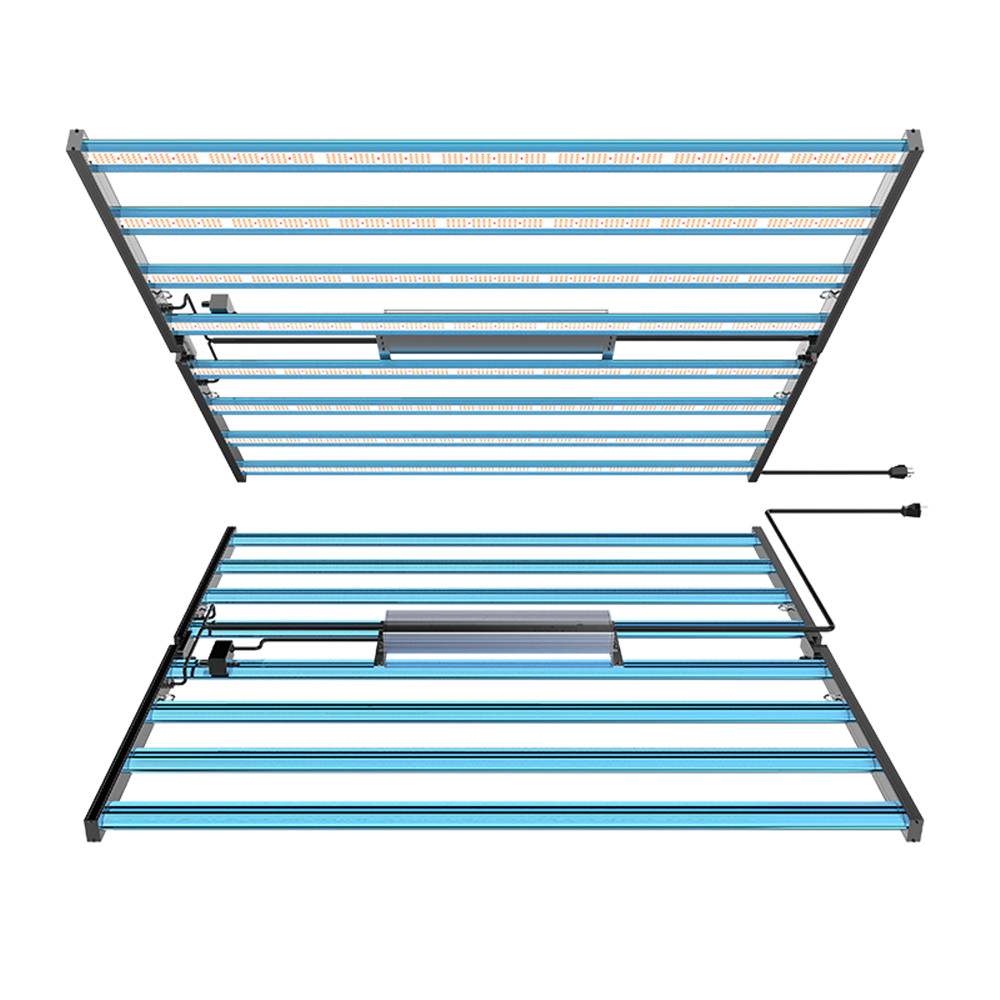

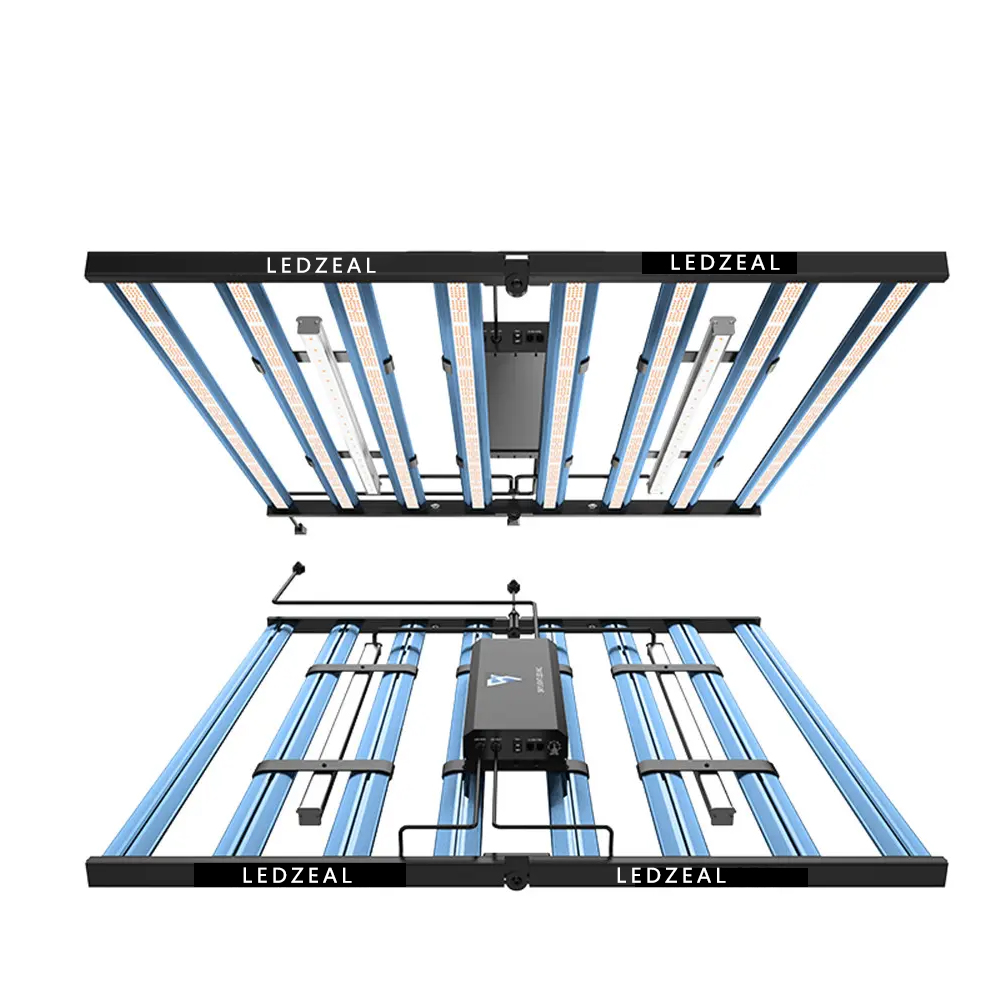

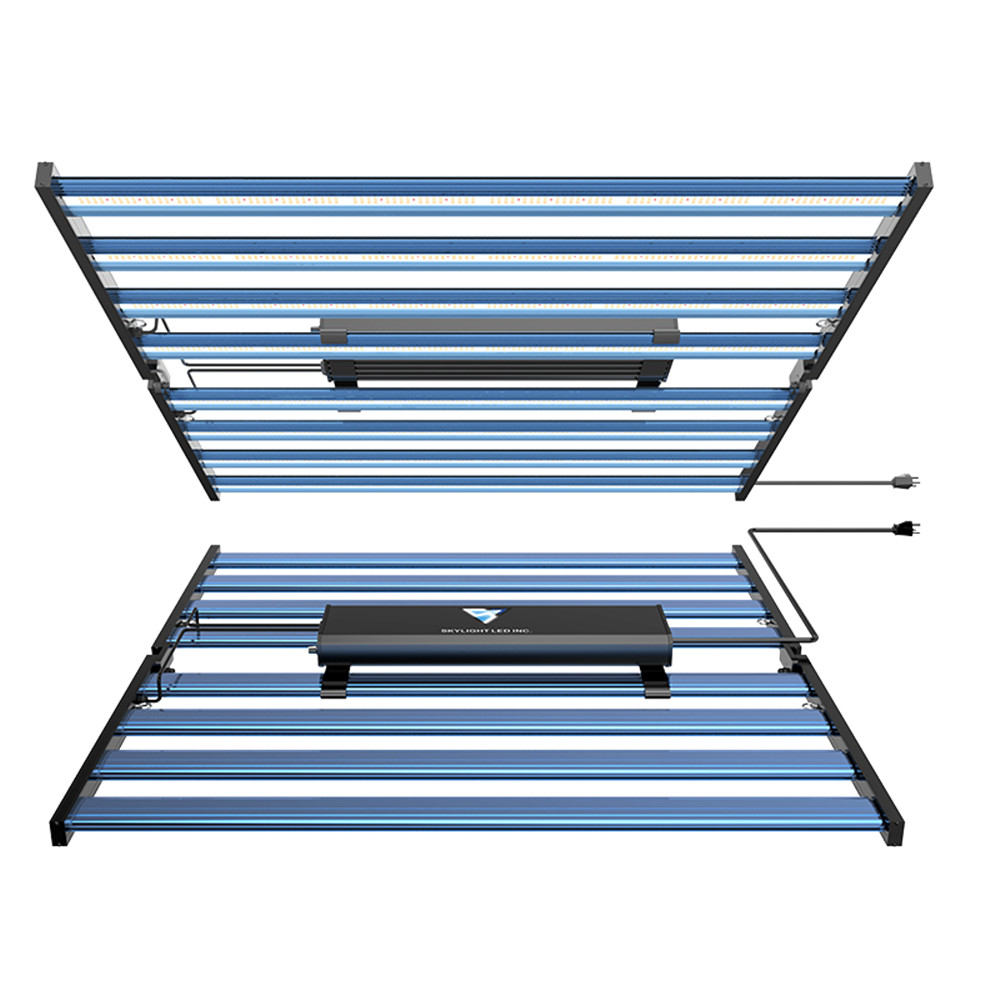

LED 1000 Pro grow lights for indoor plants

Why should LED plant lights undergo aging tests

LED grow light belongs to the electronic and electrical products, its aging test and plastic material aging focus is different, LED grow light usage process is mainly to enable it to be efficient and normal use, and the factors affecting its normal use are mainly dead lamp rate, heat dissipation, luminous efficient stability and so on. The main test method is done by increasing the voltage and current.

LED grow light belongs to the electronic and electrical products, its aging test and plastic material aging focus is different, LED grow light usage process is mainly to enable it to be efficient and normal use, and the factors affecting its normal use are mainly dead lamp rate, heat dissipation, luminous efficient stability and so on. The main test method is done by increasing the voltage and current.

LED grow light’s dead light rate test, in general, after the LED grow light is produced into a finished product. There is no problem in the studio under the rated voltage and current, but the use of the process will inevitably appear a short period of high voltage, or a sudden power off lamp situation, to ensure that this common situation occurs after the lamp can still work normally, you need to do a good test before delivery. In order to detect whether the power supply configuration is qualified, the welding position is firm, and the assembly wire withstand capacity reaches a certain standard.

LED grow light heat dissipation test, LED grow light heat dissipation performance is directly related to its service life and lamp bead luminous efficiency, aging test method is to make the LED grow light in its great withstand temperature within a certain period of time, its internal structure will not be destroyed, and within a certain period of time, the temperature of each part of the LED grow light will not increase with the lengthening of high-intensity working time.

LED grow light luminous high efficiency stability, LED grow light luminescence is efficient and stable, its main influencing factor is the rectifier voltage division capacity of the internal power supply, as long as the power supply quality is too hard, in general, within its rated service life led plant lamp can ensure efficient normal luminescence, and the general power supply will be equipped with an over voltage automatic power off device, will not have a serious impact on the lamp beads, but also does not rule out, LED grow light chip in the packaging process of the possibility of leakage, Therefore, it is also necessary to carry out flashing light tests to ensure stable and normal and efficient work.

| Model name | SKY1000PRO |

| LED quantity/brand | 3136pcs 301B+3535LED |

| PPF(umol/s) | 3205 |

| PPE(umol/s/W) | 3.018 |

| lm | 206404 |

| Housing material | All aluminum |

| Max output power | 980-1050W |

| Operating current | 10-20A |

| LED beam angle | 120 |

| Life span(hour) | 50000h |

| Power supply | SOSEN/JOSON |

| AC input voltage | 50-60HZ |

| Dimension | 1125*1160*50mm |

| Net weight | 9KG |

| Gross weight | 12.5KG |

| Power bin size | 620*170*63mm |

| Weight after packaging | 9KG |

| Certification | UL/CE/ETL/DLC |